The Tablet and Capsule Inspection Machine stands as a paramount solution for ensuring that only the highest quality tablets and capsules reach customers. Q1 features a (![]() )CE-certified design that adheres to all electrical safety compliances and is crafted to meet cGMP guidelines with compact construction and SS 316 contact parts. Designed for versatility, it requires no change parts for different shapes and sizes and incorporates a unique 360-degree rotation technique for thorough inspection. While ensuring ease of operation and maintenance. This combi machine, suitable for both tablets and capsules, guarantees minimal downtime and maximizes output with its maintenance-free components and efficient cleaning process, making it an indispensable asset in pharmaceutical manufacturing.

)CE-certified design that adheres to all electrical safety compliances and is crafted to meet cGMP guidelines with compact construction and SS 316 contact parts. Designed for versatility, it requires no change parts for different shapes and sizes and incorporates a unique 360-degree rotation technique for thorough inspection. While ensuring ease of operation and maintenance. This combi machine, suitable for both tablets and capsules, guarantees minimal downtime and maximizes output with its maintenance-free components and efficient cleaning process, making it an indispensable asset in pharmaceutical manufacturing.

Product USP

Since 2003, we have been the leading provider of next-generation automatic vision inspection systems for the pharmaceutical industry.

Premium quality, robust built, Made of solid aluminium plates.

Higher output/throughput 100000/ 125000 per hour.

High-quality electronic components.

Highly illuminated inspection zone. LUX value in the inspection zone is 2000-2500 Lumens.

Double endless belts are provided for the rotation of inspection rollers.

Specially designed electrical panel.

Sophisticated aesthetics with ergonomically designed for better operator comfort. Footrest made out closed supportive plate.

Height adjustable and lockable wheels at the bottom.

Output speed:100000 to 150000 tablets/capsules per hour.

Aesthetically superior.

CE Certified design with all Electrical Safety Compliances.

Compact design and all contact parts in SS 316 to meet cGMP guidelines.

No change parts are required for various shapes and sizes of tablets/capsules.

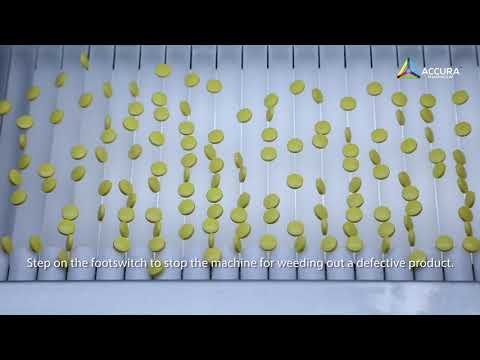

Specially designed technique for 360-degree rotation of products.

Adequately illuminated inspection zone for easy and strain-free inspection

Very easy to install, operate and maintain.

Food grade material used for plastic and rubber components.

Maintenance-free components are used to minimize downtime and maximize the output.

Quick and efficient cleaning with standard cleaning agents.

Our machine suitable for tablets and capsules.